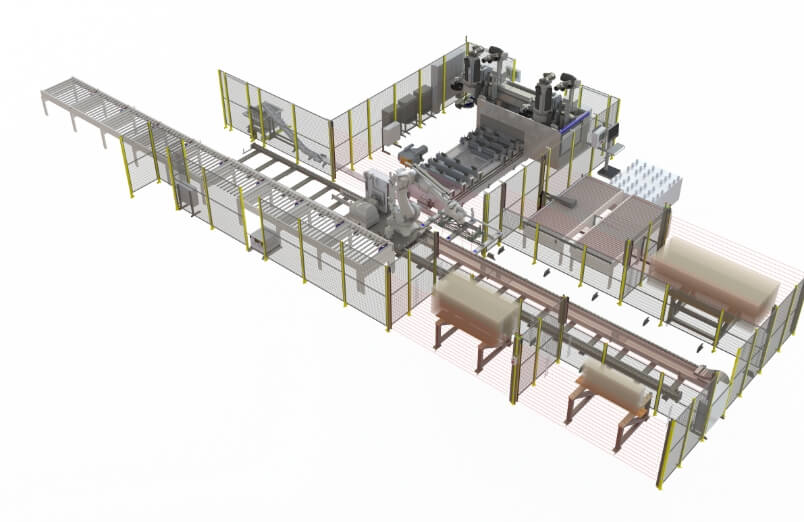

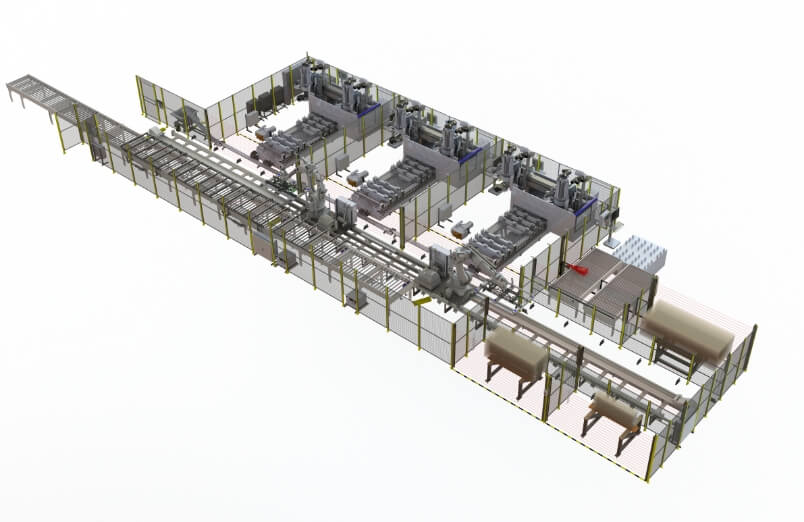

EDGE Automation was founded on, and continues to grow because of design creativity, prowess and standardization. Our configurable Pre-Engineered designs are completed and detailed to be a drop fit to our customer’s facility. However, our greatest successes result in innovation partnering with our customers.

Multiple layout configurations to suite product flow

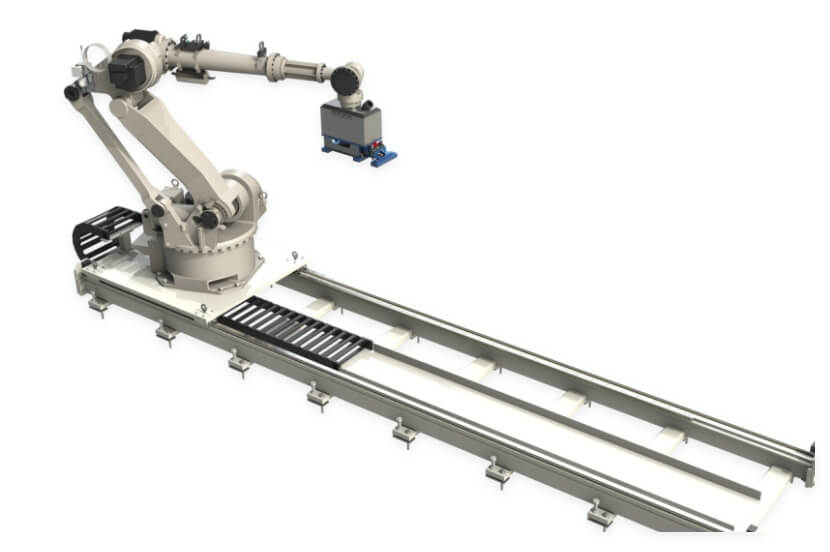

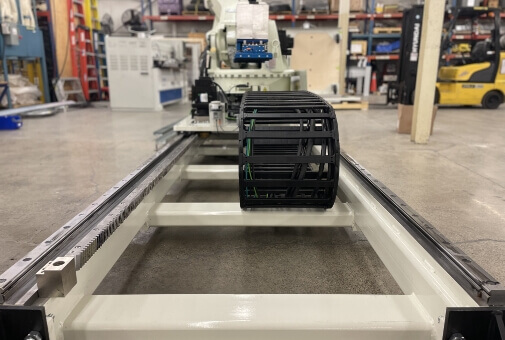

Robot on a linear rail transfer unit keeping footprint minimal

High end safety protocols using interlocks to prevent unauthorized access to restricted space

Seamless interacts with any process equipment

Vision guided pick and nesting

Max Capacity 130 lbs

Handles from 3” wide to 84” long

Max Panel size 44” x 84”

Capable for high density stacking

EDGE Automation has created this sorting solution with our partner SCM. This robotic nest unloading solution is placed of the outfeed conveyor of a nesting CNC machine equipped with automatic labelling

Robot will populate the storage locations based on predefined sorting rules as laid out in the software interface. This mode is most effective as long there are enough available storage locations for the nested product. The robot will continue to operate until all storage locations have been filled. If any position is filled, the operator must simply request to exchange the cart and the process will continue with the new empty cart.

Robot will reference the “User Defined Sorting Location” parameters. In this mode the operator will use the HMI to define each storage location within the robotic system,and use a drop-down menu to populate the product to be downstacked at each location. The operator will choose the specific part families, or common panel dimensions, to be placed on defined carts within the system. This allows the operator to choose to keep high volume panels in a storage location closer to the CNC outfeed to improve overall cell cycle.

Robot will reference any storage location parameter inputted into the system, as well as populate the remaining storage locations automatically. This allows for some flexibility between the two modes and provides a good balance for the operator. This allows the operator to identify the high-volume panels and pre-define sorting to improve overall cycle time, while minimizing the amount of customization required, as the robot will populate the remaining storage locations.

EDGE Automation's Woodworking Robotic Lean Cell

EDGE Automation's Woodworking Robotic Lean Cell

EDGE Automation's Woodworking Robotic Lean Cell

EDGE Automation was founded on, and continues to grow because of design creativity, prowess and standardization. Our Pre-Engineered designs are completed and detailed to be a dop fit to our customer’s facility. However, our greatest successes result in innovation partnering with our customers.

HanDoor™ Series V-EOAT

Vacuum Door Handling Tool - 2 Versions

(Compliant and Non-Compliant)

Blower vacuum system will manage all styles

of doors ranging in size from 1-0/4-0 in width

and 6-0/10-0 in Height.

Can manage doors with cutouts with limitations.

HanDoor™ Series S-EOAT

Servo Door Handling Tool - 2 Versions

(Compliant and Non-Compliant)

Vacuum cups are automatically positioned in an

array for positive picking.

Compressed Air Venturi vacuum system will

manage all styles of doors ranging in size from

1-0/4-0 in width and 6-0/10-0 in Height.

Can manage doors with cutouts with no

limitations.

HanDoor™ Series C-EOAT

Slab/Sheet Handling Tool

Blower vacuum system will manage all styles

of slab doors and sheet goods ranging in size

from 4ft/5ft in width and 8ft'/10ft/12ft in

Height.

Automated extension allows for thin sheet

management.

HanDoor™ Series P-EOAT

Bagged Door Handling Tool

Parallel End Grip - Compliant Pick eliminates

product sliding when gripping.

Used for handing sheets and slabs when

vacuum in not capable of picking

HanDoor™ Door / Panel handling system configured with Edge Robot Transfer Unit handle multiple flow configurations and interact with any CNC center

EDGE Automation's Dual Robot CNC Loading Cell

Robotic Loading of Doors into High Speed Finishing Line

Auto Sizing Robot Vacuum End of Arm Tool for Picking MDF Door Skins

EDGE Automation Tending System is for tending heavy payload panel/doors to the various downstream processes.

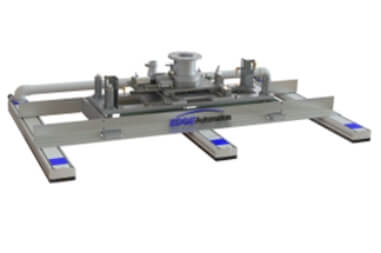

This system has been optimized for wood working industry handling required and is modular for the required transfer length.

Repeatability: +/- 0.25 mm [≈0.010 inches]

5 meter [≈15 feet] effective carriage stroke

Modular for stroke length increase in 0.5m increments

Structure designed to transport robot up to 300 kg payload

Constructed using fabricated and machined structural steel and linear ball bearing rail system

Machined steel plate construction

Battery powered automatic lubrication system included for rack and pinion.

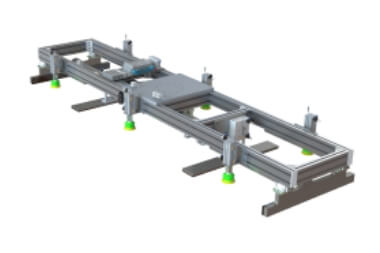

Repeatability: +/- 0.25 mm [≈0.010 inches]

10 meter [≈30 feet] effective carriage stroke

Modular for stroke length increase in 0.5m increments

Structure designed to transport robot up to 500 kg payload

Constructed using fabricated and machined structural steel and linear ball bearing rail system

Machined steel plate construction

Battery powered automatic lubrication system included for rack and pinion.

Single robot CNC Machine Tending on EDGE Robot Transfer Unit

Dual robot CNC Machine Tending on EDGE Robot Transfer Unit

EDGE Automation was founded on, and continues to grow because of design creativity, prowess and standardization. Our configurable Pre-Engineered designs are completed and detailed to be a drop fit to our customer’s facility. However, our greatest successes result in innovation partnering with our customers.